Guide to Surface Installation: Securing Play Area Edging

When designing outdoor spaces, being aware of how the different materials, elements, and pathways connect and meet is important. Over time, wear and tear can cause issues with surfaces separating if not installed with proper fixings and securing, or certain materials, like wet pour rubber can shrink away at the play area edging, creating gaps in your play surfaces.

Our surfacing experts have over 20 years of installation of a wide range of surfacing materials. Our patented installation technique to secure grass mats involves a dedication to creating a longstanding secure surface. For more details on our patented technique visit our blog.

How to Edge Artificial Grass and Hybrid Grass

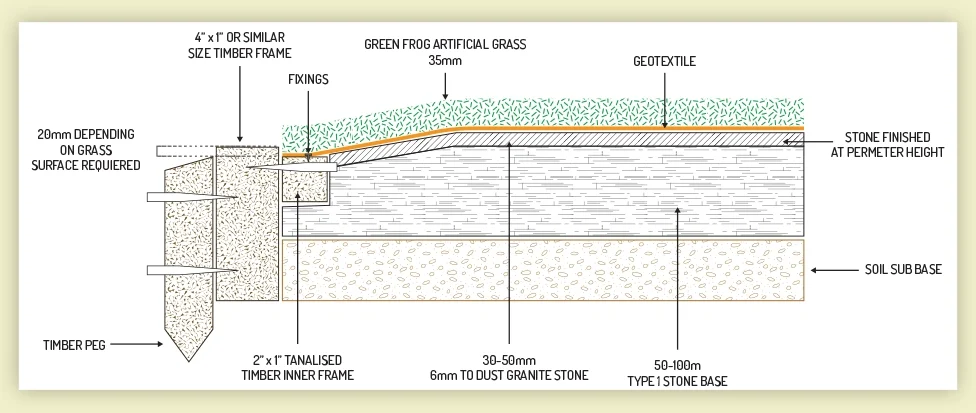

Artificial grass and hybrid grass are installed in individual rolls secured to the ground or pre-prepared sub-base. The edges of these rolls are secured by screw-type fixings into the existing ground and polymer adhesive when installed adjoining other types of surfacing.

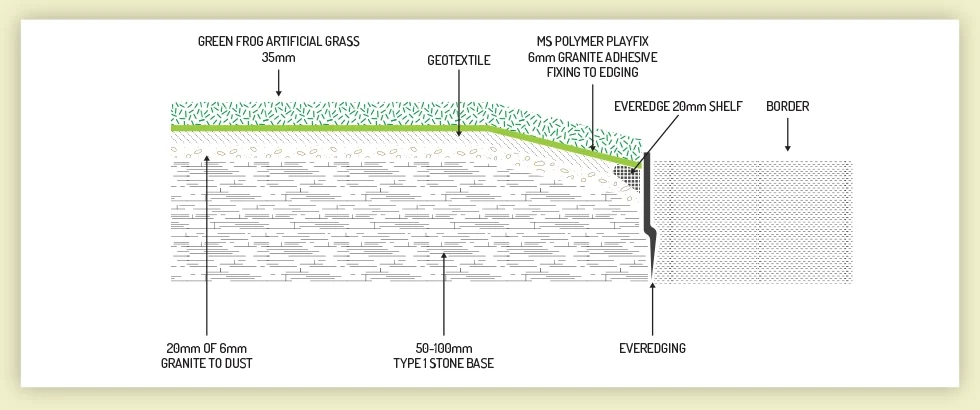

Everedging is used in installations adjoining existing hard surfaces, and fixing artificial grass to its surroundings. In the sub-base, a shelf is created on installation, maintaining a small area for shock-absorbing material along the edge of the installation allowing for movement of the surface without breaking down the new or old surface.

Securing Artificial Grass Installations with fixings limits the movement, sliding, and lifting of the rolls of artificial grass. This ensures a flat, secure surface for play and sports in areas with artificial or hybrid grass installations. These recessed smart edges create a curved edge to disguise the edges without an outer frame.

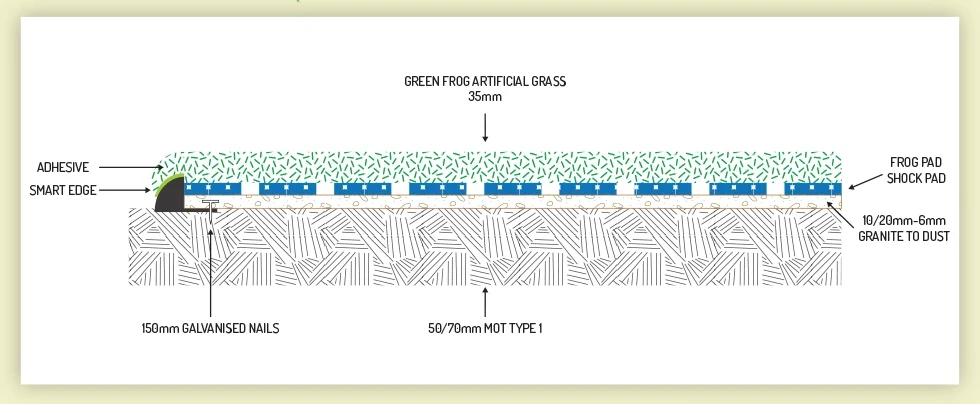

Securing Artificial Grass Installations with fixings designed to last limits the movement, sliding, and lifting of the rolls of artificial grass. This ensures a flat, secure surface for play and sports in areas with artificial or hybrid grass installations. Especially important when artificial grass is installed over a shock pad layer, smart edges create a curved edge to the surface to disguise the edges when no outer frame is installed.

Gaps and Widening Cracks in Wet Pour Solutions

Wet pour rubber is a common flooring often installed with a range of colours and patterns. The installation requires each colour to be put in place individually, with different colour blocks adjoining one another. However, over time, pressure from use or changes in temperature can cause these blocks to shrink and pull away from one another.

If this occurs in your outdoor play area, you may require playground refurbishment to prevent the cracks and gaps from widening to maintain the integrity of your surface and the patterns and images on it. EPDM rubber edging trim strips with higher tensile strength can be used to secure these weak points as part of your playground refurbishment.

EPDM is a virgin rubber surface solution that does not shrink as much as other rubber options. Available in a range of colours and widths, these can be incorporated into the existing colour theme and playground design. This provides extra security for your surface edgings without sacrificing the vibrancy and fun of your play area.

Accessibility of Play Area Edgings

Non-trip, ramped rubber edges or ‘Smart Kerbs’ are available on request for any surface installation. This creates a clean and safe transition between different parts or surfacing even if they are at different height levels. This is key to keeping your outdoor areas accessible to wheelchairs and buggies, while also reducing the risks of tripping.

Areas of artificial grass that have a SmartPlay shock pad underlay will naturally sit slightly higher than the surrounding surface. If you only need the extra height to provide safety in one area of your playground, for example: underneath playground equipment, a small ramped strip of material is perfect to make the height difference feel negligible.

PlaySmart Provides Security and Safety for your Playground Surfacing

Are you looking for a reliable, professional surfacing company for your outdoor flooring project? PlaySmart is the place to go.

Get your Free Quick Quote today or book a call with our experts using the contact form.